Accessories

Level Switch

Our organization focuses on providing high quality level switches to the clients. The product is manufactured using high quality raw material and is made available to the clients at reasonable prices. The product is passed through various quality checks.

Magnetic Level Switches

Mechanical Level Switch for liquids, The magnet equipped float follows the actual level of the liquid and magnetically triggers a Reed Switch in an identified and fixed position.

High Level Switch

Low Level Switch

-

Hysteresis (ON level/OFF Level) can be easily set at site by locating the level switch 'Up/Down' along the side walls of the tank

-

Compact Design Enables Level Sensing within 5 to 10 mm.

-

Suitable Clean Liquid

-

Two Switches Enough to Automatically Start / Stop any Pump (coupled with contactor coil)

-

Good Repeatability

-

All Plastic Construction, Corrosion Free Parts

-

Non Contact Sensing Element

Float Operated Level Switches

The Floaty Level Switch closes or opens, depending on wiring, upon reaching of an upper or lower switch point and actuates or cuts the pump.

Floaty

-

Adjustable Level Differential from 0.5 to 2 meters

-

Case and Cable Hermetically Sealed by Plastic Injection Molding

-

Suitable for Sludge/ Effluent Application

-

Corrosion Free

-

Sturdy and Durable, Need not Maintain

-

No Current / Voltage passed through water, thus No Electrolysis Salt Disposition

-

Long Life (Approximate 10 million Operations)

-

Rust Proof (Entire Sensor Body in Polypropylene)

-

Can be used in Hard Water / Fuel such as Diesel, Kerosene, Oil etc.

Applications

In overhead Tank

- Switches ON the pump when the water in overhead tank goes below the pre-decided minimum level.

- Switches OFF the pump when the water level in the overhead tank reaches the maximum level therefore prevents overflows

In underground Tank

- Switches OFF the pump when the water level reaches the minimum level in the underground tank therefore prevents dry running.

- Shall again switch ON the pump when there is sufficient water in the underground tank.

* High range on request

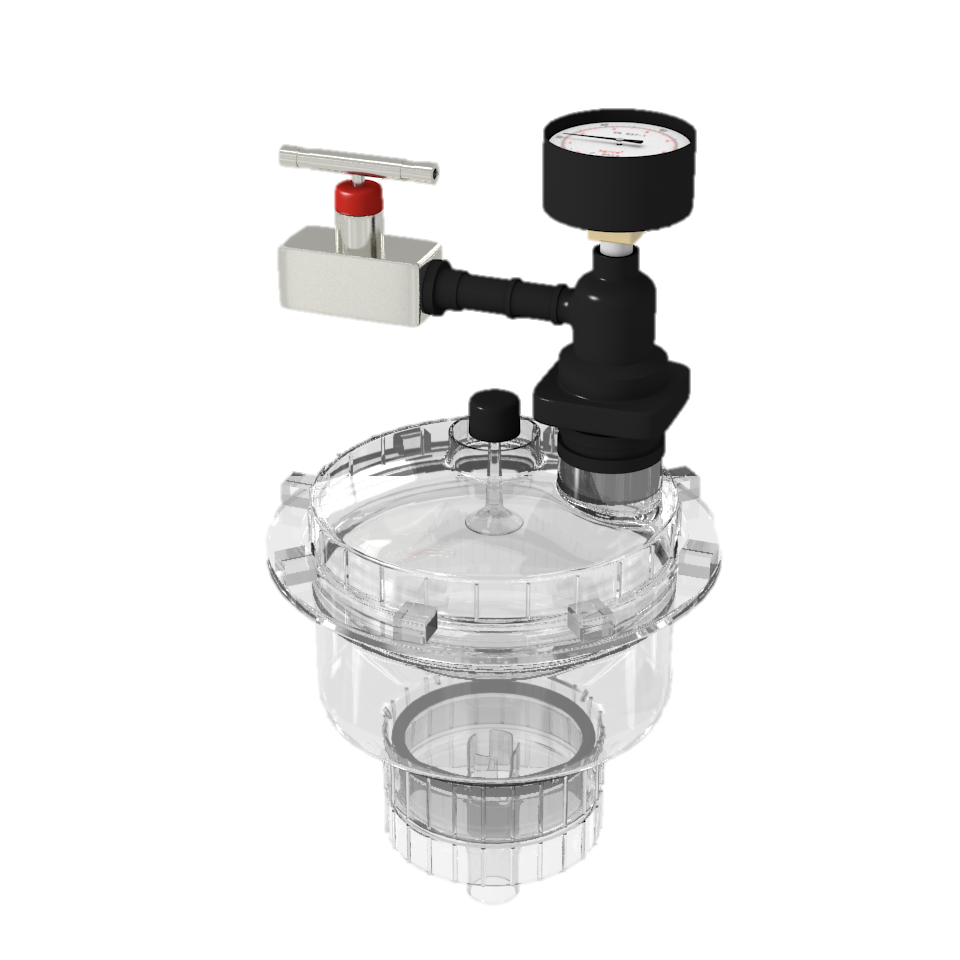

SDI Kit (Silt Density Index)

Suspended solids and colloidal materials in feed water are one of the biggest problems in reverse osmosis systems. Even though most systems have some pretreatment including 5 microns pre filters, these fine particles are responsible for fouling of reverse osmosis membranes.In order to have some measure of the degree of this fouling problems, a concept called silt density index is used. Here a 0.45 microns filter is exposed to the feed water under pressure and filtration rates are calculated.A detailed description of the test is available in our operating manual. *500 ml. measuring beaker and 0.45 micron filter paper.

-

Integral SS Needle Valve for Pressure Control

-

Quick Release Coupling Making Multi-point Sampling Convenient

-

40mm dia. 0-7 kg/cm2 On Line Pressure Gauge

-

Automatic Release Valve

-

Transparent Body

-

500 ml Beaker for Sampling

-

Best Way to Enhance the Life of your Membrane

Hardness Test Kit

-

Useful for Raw as well as Soft Water Hardness Analysis

-

Measurement Accuracy: Raw water = /+ 25 ppm ;Soft water = /+1 ppm

-

Plastic Measurement as well as Reagent Bottles without any delicate Glass Apparatus

-

Reagents Available in 30 ml as well as 100 ml Packing

-

Also Available as Refill Packs

-

Marked Bottles are Provided for Easy Measurement

-

Each Unit Comes With Instructions for Measurement Procedure

-

Air Tight Packing Ensures Long Life of Reagents